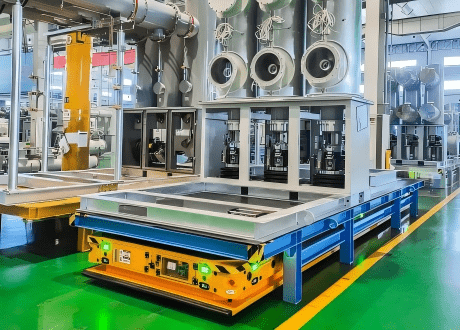

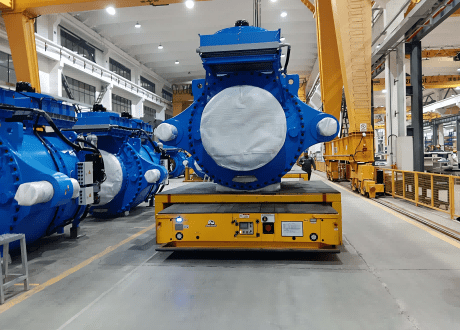

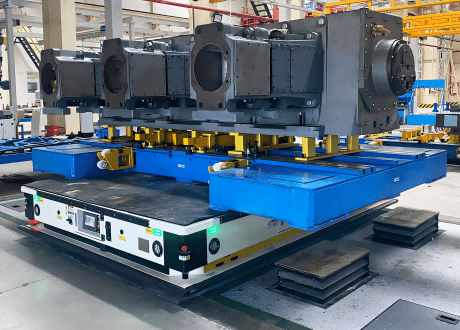

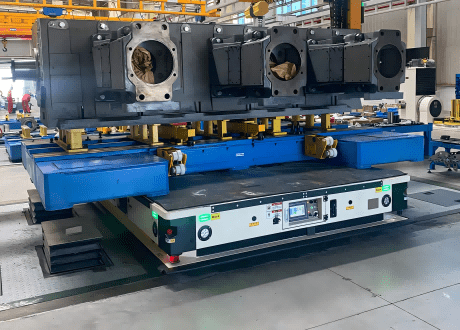

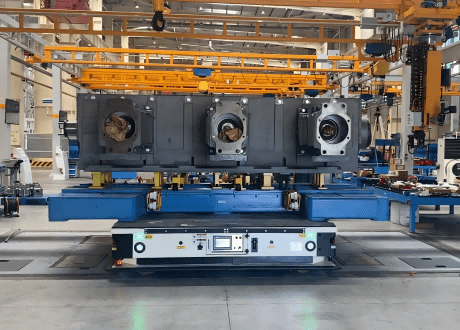

40T Heavy-duty Omnidirectional AGV for Workshop Assembly Transport

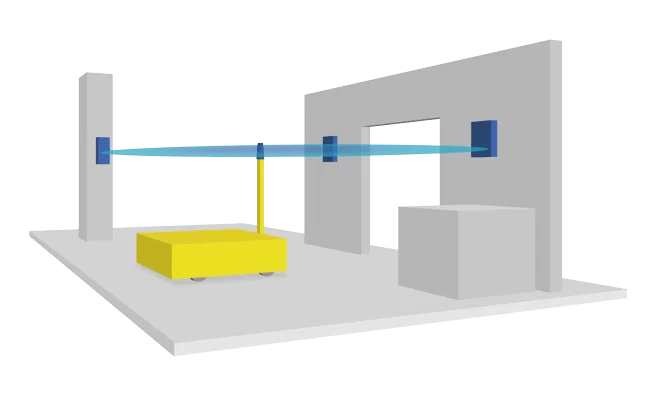

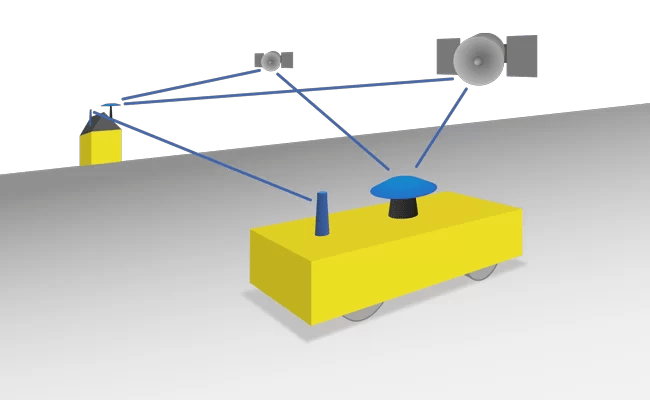

In petrochemical and heavy equipment manufacturing, transporting oversized components during assembly is often inefficient and risky when relying on forklifts or cranes. To address these challenges, a 40T heavy-duty omnidirectional AGV has been developed for automated transfer in main unit and final assembly areas. Equipped with laser navigation indoors and magnetic guidance outdoors, it ensures reliable operation in varied environments, including rainy conditions. The AGV integrates with floor lifting mechanisms via PLC and scheduling systems to enable precise docking and synchronized assembly line operations.

40t load capacity: Designed for oversized assembly components.

Lifting function: Enables precise docking and transfer.

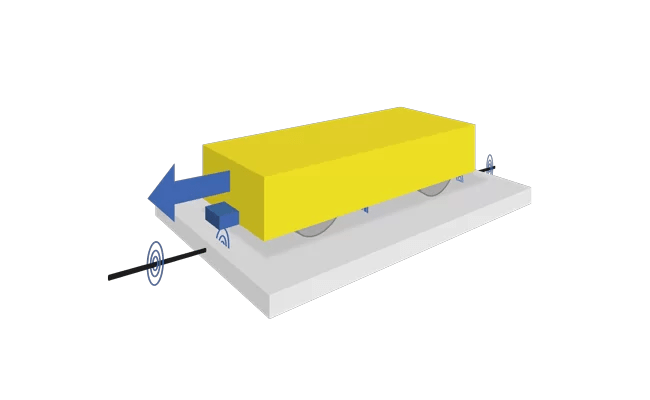

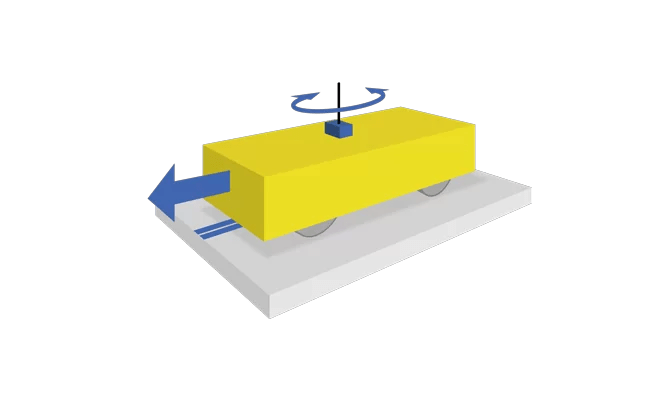

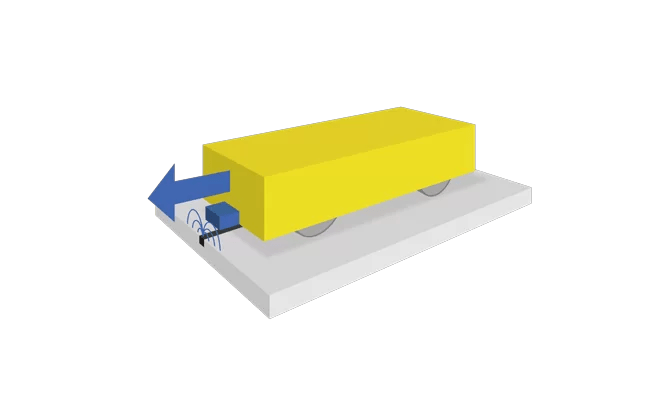

Omnidirectional mobility: Smooth movement in any direction, loaded or unloaded.

Dual navigation system: Laser indoors, magnetic guidance outdoors.

System integration: PLC-linked with floor lifting mechanisms for synchronized operations.

Safety & efficiency: Reduces manual handling risks and improves assembly productivity.

Capacity | from 1 ton to over 1000 tons |

Dimensions | on request |

Steering systems | front axle, all axles, ± 90° steering, omnidirectional |

Power supply | battery (electric grid or diesel generator on request) |

Travel speed | on request (from 1 km/h to 6 km/h) |

Drive motors | AC motors (hydraulic motors on request) |

Steering motors | AC motors (hydraulic motors on request) |

Command | touch panel on board, notebook/s, pulpits, customer WMS/ERP |

Navigation technologies | inductive, magnetic, laser, natural, dGPS, optical, inertial |

Kind of wheels | solid rubber, polyurethane, pneumatic |

Lifting deck | on request (lifting stroke from 50 mm) |

Kind of battery | lead acid, gel, lithium, pure lead |

Battery life | on request (from 1500 m to over 15000 m) |

Climbing ability | on request (from 1% to over 20%) |

Operating environment | indoor, outdoor, offshore |

Safety devices | laser scanners, sensitive bumpers, ultrasonic sensors |

Our heavy-duty AGVs are distinguished in the global market by their advanced load-handling capabilities combined with versatile navigation options. Each project is tailored in close cooperation with the customer, ensuring that the selected guidance technology—or a hybrid approach—aligns with operational demands, environmental conditions, and cost considerations. A variety of navigation systems are available to guarantee precise, safe, and efficient transport for heavy and oversized loads.

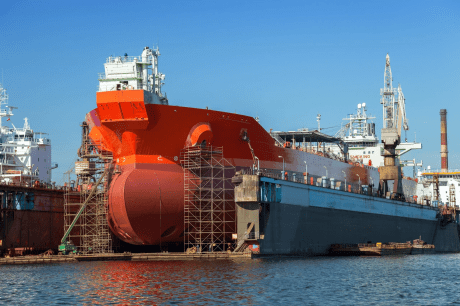

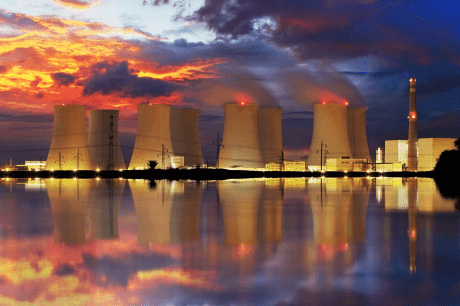

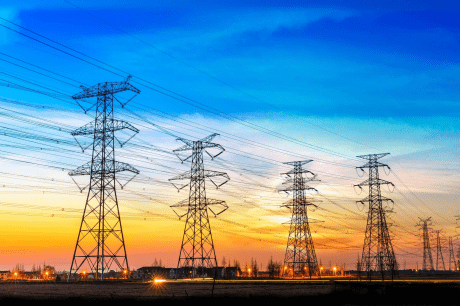

AGVs play a vital role across diverse industries—from automotive and defence to shipyards, nuclear, oil & gas, power generation, steel, and wind power—offering safe, precise, and efficient handling of heavy and oversized loads. They are widely used in transporting power transformers, precast concrete, marble, natural stones, and steel components, as well as in railway and foundry operations, ensuring flexible logistics and optimized in-plant material flow.