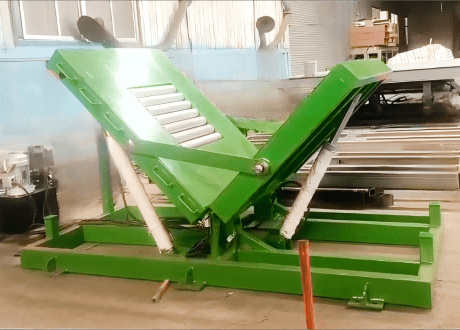

Levantador de bobinas hidráulico de 90 graus de 3 toneladas

O levantador de bobinas hidráulico de 90 graus de 3 toneladas é utilizado para rodar bobinas de arame a 90 graus utilizando uma bomba hidráulica eléctrica e cilindros de dupla ação. A primeira plataforma possui rolos para posicionar a bobina e um suporte de cintagem para a fixar durante a rotação. A segunda plataforma é móvel, permitindo a fácil inserção de ferramentas de elevação antes da rotação. Após a rotação, a bobina é retirada por uma grua e o sistema é reiniciado automaticamente. Suporta até 3 toneladas e garante um manuseamento seguro, estável e eficiente das bobinas.

Modelo | FZPT-3000 |

Dimensões da plataforma | 1600*1300+1300*1300mm |

Capacidade de carregamento | 3.000KG |

Ângulo de inclinação | 90° |

Velocidade de inclinação | 60S |

Método de inclinação | Hidráulico |

Nota: Os parâmetros acima são apenas para referência, todos os produtos podem ser personalizados | |

Rotação hidráulica de 90° da bobina: O equipamento utiliza uma estação de bomba hidráulica eléctrica para acionar cilindros hidráulicos de dupla ação, permitindo uma viragem suave e controlada de 90 graus das bobinas de arame. Esta conceção assegura um funcionamento estável e um posicionamento preciso durante todo o processo de viragem.

Primeira plataforma com rolos integrados: A primeira plataforma está equipada com uma secção de rolos (700 × 700 mm) que permite um movimento horizontal fácil e o posicionamento da bobina. Isto ajuda a garantir que a extremidade da bobina está bem alinhada contra a segunda plataforma para uma operação de inversão precisa.

Suporte de cintagem para fixação de bobinas: Um suporte de cintagem incorporado na parte lateral da primeira plataforma permite aos operadores fixar firmemente a bobina com cintas, eliminando o risco de deslizamento ou deslocação durante a rotação. Esta caraterística aumenta a segurança e a estabilidade.

Segunda plataforma móvel: A segunda plataforma (1300 × 1300 mm) foi concebida para ser móvel e reposicionável. Antes de inverter, os operadores podem facilmente inserir ferramentas de elevação ou dispositivos de elevação de bobinas na bobina. Uma vez no lugar, a plataforma é reposicionada para suportar o processo de inversão.

Função de reposição automática: Depois de a bobina ser virada e removida - normalmente utilizando uma ponte rolante - os cilindros hidráulicos retraem-se para devolver ambas as plataformas às suas posições originais, prontas para a operação seguinte. Este ciclo assegura uma rápida rotação e uma maior eficiência operacional.