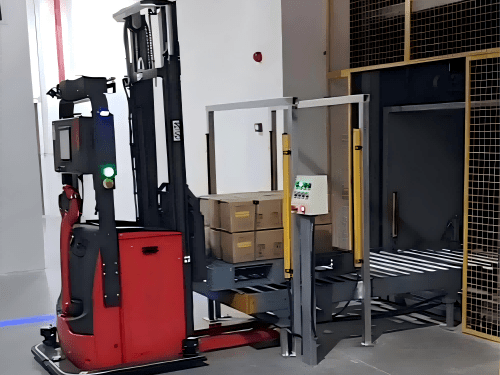

VRC| Automated VRC Lift with AGVs

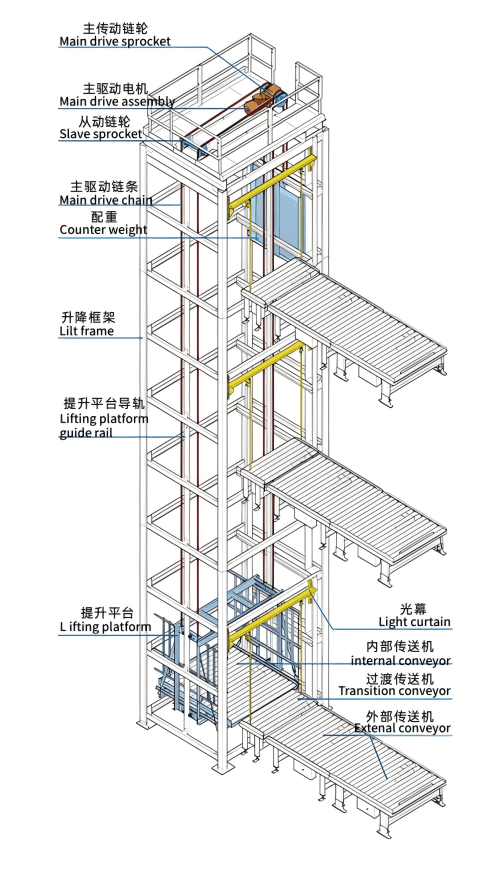

The Automated VRC lift with AGV is an efficient material handling device specifically designed to work in conjunction with Automated Guided Vehicle (AGV) systems. By seamlessly integrating with AGVs, this lift facilitates automated vertical transportation of materials, thereby enhancing the overall efficiency of the logistics system.

| Model |

Automated VRC lifts with AGVs |

| Lifting Capacity | Max.5000kg |

| Lift Speed | Max.60m/min |

| Lifting Stroke | 0-50m |

| Conveying Cycle | >15s/piece (depending on the stroke) |

| Load/Unload Patterns | “C” “Z” “E” pattern (Optional) |

| Levels | 1 to 6 stops (Customized) |

| Power Supply | 230V/3P or 460V/3P |

| Application | Moving heavy boxes, cargo, and pallets from one level to another. |

- Automated Integration: The lift is designed to work seamlessly with AGV systems, enabling automated loading and unloading of materials, which reduces manual intervention and increases operational efficiency.

- High-Efficiency Vertical Transport: The lift provides stable and rapid vertical transportation of materials between different floors, meeting the demands of multi-level material handling.

- Flexible Adaptability: The system can be customized to accommodate various types and sizes of materials, ensuring optimal compatibility with diverse operational requirements.

- Space-Saving Design: With its compact structure, the lift occupies minimal floor space, making it ideal for environments with limited space availability.

Our Automated VRC lift with AGV offers customized services to meet various application needs. The platform size, load capacity, and lift height can be tailored according to the specific operational requirements, ensuring optimal compatibility. Additionally, the system supports various conveyor integration options, including roller conveyors, chain conveyors, and plate chain conveyors, providing flexibility for different logistics workflows and enhancing operational efficiency.

The Automated VRC lift with AGV is widely used in multi-level warehouses, production workshops, distribution centers, and other locations, especially in environments where vertical material transportation between multiple floors is required. By seamlessly integrating with AGV systems, it enables automated loading and unloading of materials, reducing manual intervention and improving operational efficiency. Its efficient vertical transport function meets the material transfer needs between multiple floors, optimizing logistics processes and enhancing overall production efficiency.