VRC| Convoyeur à piston vertical extérieur

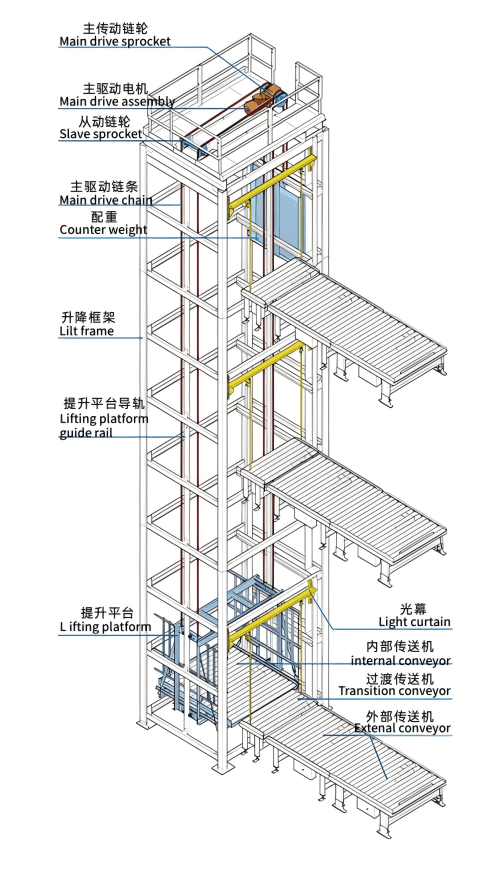

Ce convoyeur alternatif vertical d'extérieur est conçu pour le transport vertical de marchandises sur plusieurs étages dans des environnements poussiéreux. Le système comprend une plate-forme élévatrice (1400×1600 mm) avec des rouleaux en acier inoxydable. La surface des rouleaux se trouve à 2100 mm sous le sommet de la cabine et comprend des dispositifs antidérapants et de positionnement. La capacité de charge est de 2 tonnes, avec une hauteur de levage de 16 mètres et une vitesse ≥30 m/min. Trois postes de commande au sol, résistants à la poussière et à l'eau, sont fournis, chacun avec des boutons-poussoirs et un arrêt d'urgence (type non tactile, adapté aux environnements poussiéreux). Ce système de convoyage assure une manutention sûre, efficace et automatisée des matériaux sur plusieurs niveaux.

| Modèle | Convoyeur alternatif vertical pour l'extérieur |

| Capacité de levage | Max. 2000 kg |

| Vitesse de levage | 30m/min |

| Course de levage | 16m |

| Dimensions de la plate-forme | 1600*1600*2400mm |

| Modèles de chargement/déchargement | Modèle "Z" (en option) |

| Niveaux | 3 arrêts (sur mesure) |

| Alimentation électrique | 15kW |

| Application | Déplacer des boîtes lourdes, des cargaisons et des palettes d'un niveau à l'autre. |

Système de transport durable : Équipé de rouleaux en acier inoxydable 201 (Ø80 mm, pas de 150 mm, largeur nette de 1400 mm) pour une résistance à la corrosion et un mouvement stable.

Caractéristiques de sécurité intégrées : La surface antidérapante et les mécanismes de positionnement à l'intérieur de la plate-forme élévatrice garantissent un transport sûr des marchandises.

Système de contrôle efficace : Contrôlé par PLC avec interface à écran tactile, affichage des défauts en temps réel, journaux des opérations et commutation de mode manuel/automatique.

Postes d'opérateur étanches à la poussière : Trois colonnes de commande au sol avec commande par bouton-poussoir et arrêt d'urgence, conçues sans écran tactile pour les environnements poussiéreux.

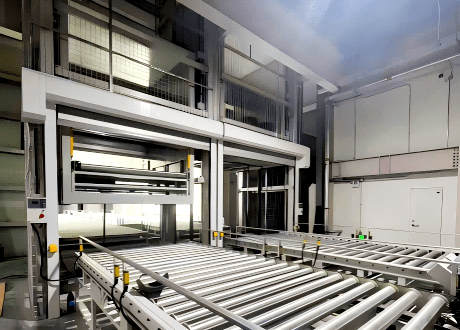

Stations tampons flexibles : Plusieurs zones tampons à hauteur réglable à chaque étage permettent un chargement et un déchargement en douceur.

Conception adaptée à l'extérieur : Conçus pour des performances fiables dans des environnements extérieurs difficiles et exposés à la poussière.

Notre convoyeur vertical à piston pour l'extérieur offre des services personnalisés pour répondre aux besoins de diverses applications. La taille de la plate-forme, la capacité de charge et la hauteur de levage peuvent être adaptées aux exigences opérationnelles spécifiques, garantissant ainsi une compatibilité optimale. En outre, le système prend en charge diverses options d'intégration de convoyeurs, notamment des convoyeurs à rouleaux, des convoyeurs à chaîne et des convoyeurs à chaîne à plaques, ce qui offre une certaine souplesse pour différents flux logistiques et améliore l'efficacité opérationnelle.

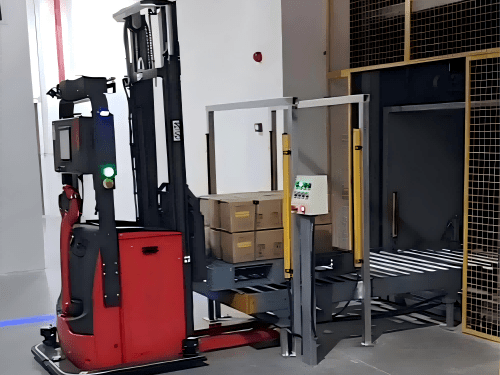

Le convoyeur alternatif vertical extérieur est largement utilisé dans les entrepôts à plusieurs niveaux, les ateliers de production, les centres de distribution et d'autres lieux, en particulier dans les environnements où le transport vertical de matériaux entre plusieurs étages est nécessaire. En s'intégrant parfaitement aux systèmes AGV, il permet le chargement et le déchargement automatisés des matériaux, réduisant ainsi les interventions manuelles et améliorant l'efficacité opérationnelle. Sa fonction de transport vertical efficace répond aux besoins de transfert de matériaux entre plusieurs étages, optimisant les processus logistiques et améliorant l'efficacité globale de la production.