Système de table basculante hydraulique pour noyaux de fer de 50 tonnes

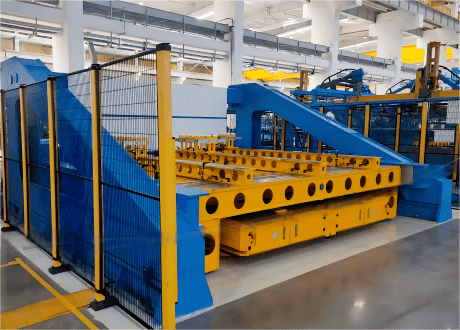

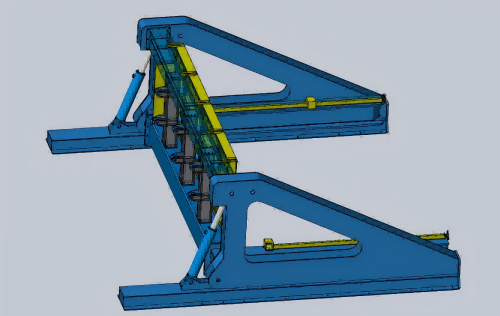

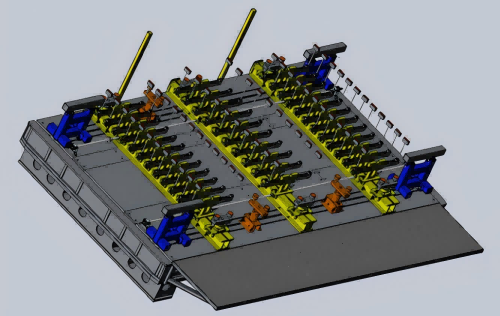

Le système de table basculante hydraulique pour noyaux de fer de 50 tonnes est un équipement spécialisé conçu pour l'assemblage, le retournement et le positionnement vertical de grands noyaux de transformateurs à deux ou trois colonnes. Le système comprend une plate-forme de retournement hydraulique en surface (composée du corps de la table de retournement, du système hydraulique, du système de contrôle électrique et du système de protection de sécurité), une plate-forme d'empilage, un support de levage motorisé, un outil de support auxiliaire et d'autres installations associées.

Capacité de chargement maximale | 50 tonnes |

Dimensions du noyau rabattable | 4300mm*3400mm |

Dimensions de la plate-forme empilable | 3500 mm (L) × 4300 mm (L) × 1250 mm (H) |

Angle de rotation | 0-90° |

Perpendicularité Précision | ±0.5° |

Planéité de la plate-forme | ≤3 mm (écart local ≤2 mm/m) |

Rugosité de la surface de la plate-forme | ≤12.5 μm |

Temps de rotation (0° à 90°) | ≤10 minutes (réglable) |

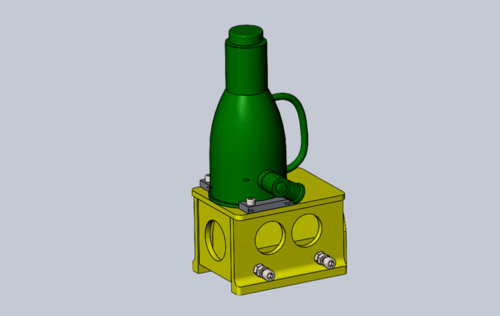

Puissance du moteur hydraulique | ≤55 kW |

Pression de service du système hydraulique | 18 MPa - 25 MPa |

Note : Les paramètres ci-dessus sont donnés à titre indicatif, tous les produits peuvent être personnalisés. | |

Le système comprend une plate-forme basculante hydraulique en surface (composée du corps de la table tournante, du système hydraulique, du système de commande électrique et du système de protection), une plate-forme d'empilage, un support de levage motorisé, un outil de soutien auxiliaire et d'autres installations associées.

Système de basculement hydraulique efficace et sûr

Utilise un entraînement hydraulique pour effectuer un retournement stable et en douceur des noyaux sans avoir recours à un pont roulant. Équipé de fonctions hydrauliques d'autoblocage et d'autocontrôle pour garantir un fonctionnement sûr pendant toute la durée du processus de retournement.Conception structurelle robuste et durable

Les principaux composants sont soudés à partir d'acier de construction et de plaques d'acier à haute résistance, ce qui leur confère une solidité et une rigidité excellentes pour supporter les charges pendant l'empilage et le tournage des carottes.Intégration modulaire pour un fonctionnement coordonné

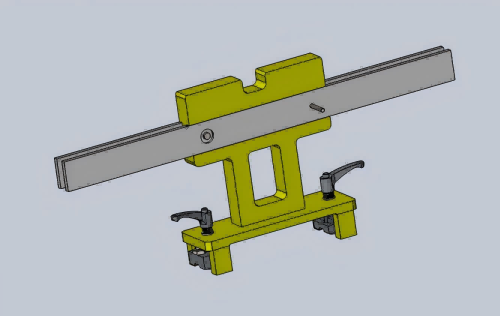

La table tournante et la plate-forme d'empilage sont reliées par des rails de guidage, des limiteurs et des mécanismes de vérins pour un alignement rapide et précis et un verrouillage sûr, ce qui permet un flux de travail efficace.Adaptabilité à de multiples modes de travail

Prend en charge trois modes de fonctionnement : "Production de base", "Maintenance de base" et "Débogage", pour répondre à différents besoins opérationnels. Le mode débogage comprend un contrôle d'accès pour une sécurité accrue.Ensemble complet de dispositifs auxiliaires

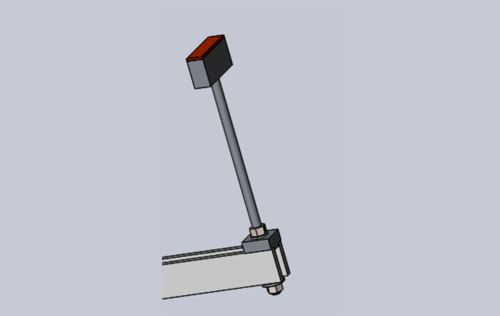

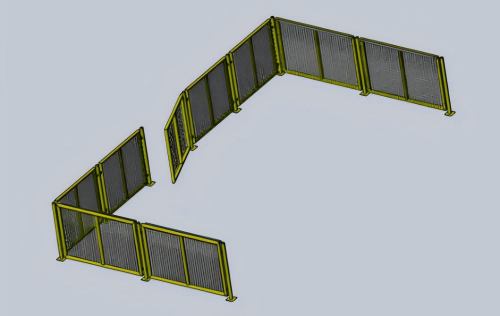

Il comprend une plate-forme d'empilage (avec poutres longitudinales), un support de colonne de noyau, un support latéral de colonne de noyau, un support de fer à étrier et une barrière de sécurité, formant ainsi une solution complète pour les opérations de retournement de noyau de transformateur.Convivialité et automatisation poussée

Contrôlé par des programmes PLC et exploité par un panneau de commande convivial, il permet un changement de mode rapide, des mouvements synchronisés et une intervention manuelle réduite.