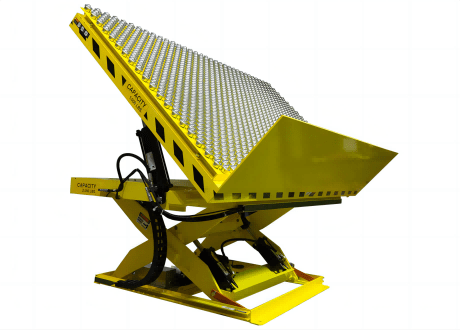

Upender hydraulique de 15 tonnes à 90 degrés

L'élévateur hydraulique à 90 degrés de 15 tonnes est conçu pour faire passer les chemises de cylindres de la position horizontale à la position verticale (0-90°) au cours de la production. Elle est dotée d'une grande plate-forme double (environ 4800×2600 mm + 2600×2000 mm) pour s'adapter à différentes tailles de chemises. La table s'élève légèrement au-dessus du sol à 0° et s'abaisse partiellement dans une fosse à 90°, avec une plate-forme d'opérateur rétractable en forme d'arc (charge maximale : 200 kg) pour un accès sûr. La table de travail comprend quatre supports à rouleaux ou plus, avec des rouleaux entraînés par des vis et des rails qui se déplacent horizontalement et verticalement grâce à une commande électrique pour s'adapter aux différents diamètres de gaine.

Modèle | FZPT-15000 |

Dimensions de la plate-forme | 4800*2600mm+2600*2000mm |

Capacité de chargement | 15 000 KG |

Angle d'inclinaison | 90° |

Vitesse de basculement | 70S |

Méthode d'inclinaison | Hydraulique |

Note : Les paramètres ci-dessus sont donnés à titre indicatif, tous les produits peuvent être personnalisés. | |

Dispositifs d'arrêt d'urgence multiples

Équipé d'au moins deux interrupteurs d'arrêt d'urgence. Le système de commande comprend un bouton d'arrêt d'urgence qui interrompt immédiatement le fonctionnement de l'appareil lorsqu'il est actionné.Vérins hydrauliques antidéflagrants

Chaque vérin comprend une soupape de sécurité intégrée qui bloque l'huile hydraulique en cas de rupture ou de détachement du tuyau, évitant ainsi les chutes brutales.Descente de pression hors tension

La centrale hydraulique est équipée d'une soupape de surpression qui permet à la plate-forme de descendre par gravité en cas de perte de puissance.Maintien automatique de la pression en cas de panne de courant

En cas de panne de courant, le système maintient automatiquement la pression afin de préserver la stabilité de la plate-forme et d'éviter toute inclinaison ou chute dangereuse.Butées mécaniques à 0° et 90°.

Des butées mécaniques placées à des endroits clés empêchent toute rotation excessive et garantissent que la pièce à usiner reste bien en place.Mécanisme d'auto-verrouillage hydraulique

La plate-forme se verrouille automatiquement à l'arrêt. Elle ne s'abaisse pas en cas de perte de puissance ou de fuite hydraulique.Clôtures de sécurité et verrouillages

Des barrières de protection et des systèmes de verrouillage sont installés autour de l'upender pour empêcher le personnel de pénétrer dans la zone de rotation pendant le fonctionnement.