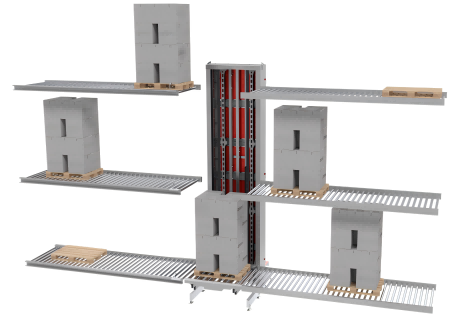

Автоматизированная система VRC для AGV

Автоматизированная система VRC (Vertical Reciprocating Conveyor) для AGV разработана для обеспечения беспрепятственной вертикальной транспортировки материалов между этажами на интеллектуальных фабриках и в логистических центрах. Она интегрируется с автоматизированными управляемыми транспортными средствами для обеспечения плавной погрузки и разгрузки, гарантируя эффективный поток материалов в многоуровневых производственных или складских помещениях. Система оснащена приводом с управлением от ПЛК и технологией преобразования частоты для стабильной и точной работы подъемника. Кабина оснащена роликами с приводом, которые работают в координации с AGV, обеспечивая полностью автоматизированное перемещение грузов без ручного вмешательства.

Модель | SJD0.5-6.2 |

Размеры кабины | W1400* L1600*H2000 мм |

Грузоподъемность | 500 КГ |

Высота перемещения | 6200 мм |

Количество уровней | 2 остановки |

Шаблоны загрузки/разгрузки | Шаблон "C" |

Скорость подъема | 30 м/мин |

Система управления | ПЛК + преобразователь частоты |

Длина конвейерного ролика | 1F: 4700 мм, 2F: 1500 мм |

Примечание: Вышеуказанные параметры приведены только для справки, все продукты могут быть настроены | |

Бесшовная интеграция с AGV

Система специально разработана для совместной работы с автоматизированными транспортными средствами. Благодаря роликовым конвейерам с приводом внутри кабины и на каждом уровне пола, AGV могут загружать и выгружать товар автоматически, исключая ручное управление и обеспечивая непрерывный и эффективный рабочий процесс.Эффективная вертикальная транспортировка

Действуя как вертикальная связь между этажами, система VRC обеспечивает плавное и быстрое перемещение товаров на многоуровневых предприятиях или складах. Это обеспечивает оптимизацию материального потока, сокращает время ожидания и повышает общую производительность интралогистических операций.Передовая система управления

Оснащенный ПЛК и системой преобразования частоты, подъемник работает со стабильным контролем скорости, точным позиционированием, плавным ускорением и замедлением. Это минимизирует механические нагрузки, снижает потребление энергии и обеспечивает надежную долгосрочную работу.Высокая безопасность и чистый дизайн

Кабина и окружающая конструкция полностью закрыты панелями из цветной стали, что предотвращает проникновение пыли и повышает чистоту рабочего места. Высокоскоростные рулонные ворота обеспечивают безопасный и контролируемый доступ, сокращая время простоя между операциями.