Sistema hidráulico de mesa basculante con núcleo de hierro de 50 toneladas

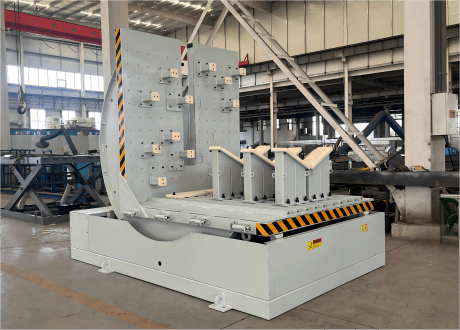

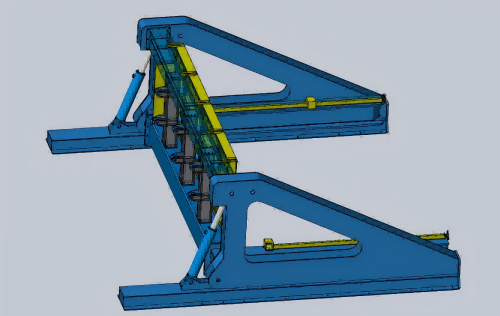

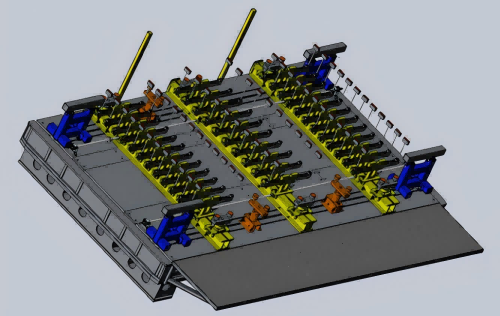

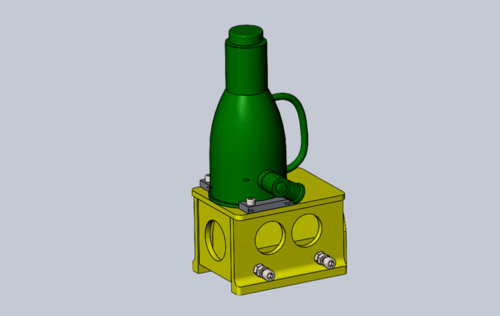

El sistema de mesa giratoria hidráulica para núcleos de hierro de 50 toneladas es un equipo especializado diseñado para el montaje, giro y posicionamiento vertical de grandes núcleos de transformadores de dos y tres columnas. El sistema incluye una plataforma de giro hidráulica sobre el suelo (compuesta por el cuerpo de la mesa de giro, el sistema hidráulico, el sistema de control eléctrico y el sistema de protección de seguridad), una plataforma de apilamiento, un bastidor de soporte de elevación motorizado, herramientas de soporte auxiliares y otras instalaciones asociadas.

Capacidad máxima de carga | 50 toneladas |

Dimensiones del núcleo abatible | 4300mm*3400mm |

Dimensiones de la plataforma apilable | 3500 mm (ancho) × 4300 mm (largo) × 1250 mm (alto) |

Ángulo de giro | 0-90° |

Precisión de perpendicularidad | ±0.5° |

Planitud de la plataforma | ≤3 mm (desviación local ≤2 mm/m) |

Rugosidad de la superficie de la plataforma | ≤12,5 μm |

Tiempo de giro (0° a 90°) | ≤10 minutos (ajustable) |

Potencia del motor hidráulico | ≤55 kW |

Presión de trabajo del sistema hidráulico | 18 MPa - 25 MPa |

Nota: Los parámetros anteriores son sólo para referencia, todos los productos pueden ser personalizados | |

El sistema incluye una plataforma basculante hidráulica sobre el suelo (compuesta por el cuerpo de la mesa giratoria, el sistema hidráulico, el sistema de control eléctrico y el sistema de protección de seguridad), una plataforma de apilamiento, un bastidor de soporte de elevación motorizado, utillaje de soporte auxiliar y otras instalaciones asociadas.

Sistema de inclinación hidráulico eficaz y seguro

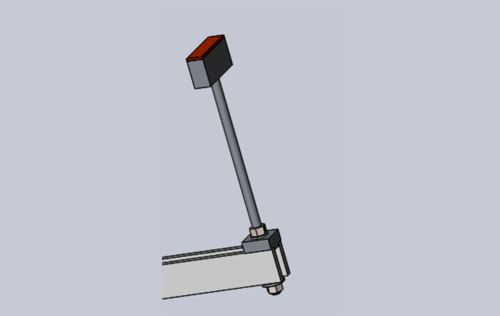

Utiliza un accionamiento hidráulico para realizar el volteo del núcleo de forma estable y suave sin necesidad de puente grúa. Equipado con funciones hidráulicas de autobloqueo y autocomprobación para garantizar un funcionamiento seguro durante todo el proceso de volteo.Diseño estructural robusto y duradero

Los componentes principales están soldados a partir de acero estructural de alta resistencia y chapas de acero, lo que proporciona una excelente resistencia y rigidez para soportar las cargas durante el apilado y giro del núcleo.Integración modular para un funcionamiento coordinado

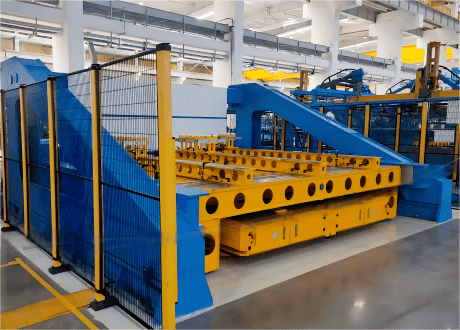

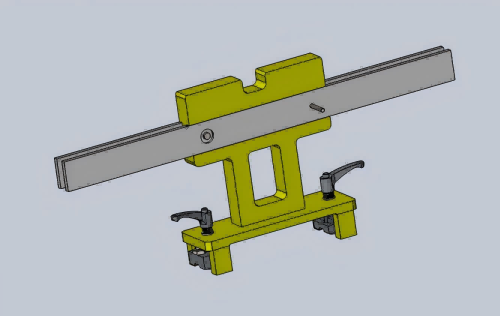

La mesa giratoria y la plataforma de apilamiento están unidas con carriles guía, limitadores y mecanismos de elevación para una alineación rápida y precisa y un bloqueo seguro, lo que permite un flujo de trabajo eficaz.Adaptabilidad a múltiples modos de trabajo

Admite tres modos de funcionamiento: "Core Production", "Core Maintenance" y "Debugging", para satisfacer distintas necesidades operativas. El modo de depuración incluye control de acceso para mejorar la seguridad.Juego completo de accesorios auxiliares

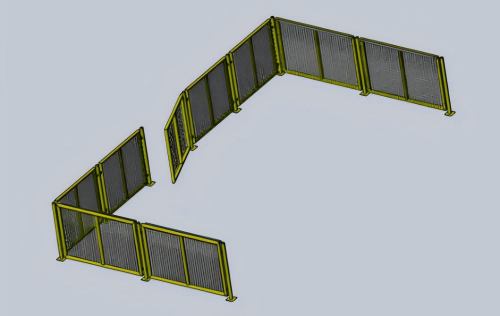

Incluye plataforma de apilamiento (con vigas longitudinales), soporte de columna de núcleo, soporte lateral de columna de núcleo, soporte de hierro de yugo y valla de seguridad, formando una solución integral para las operaciones de torneado de núcleos de transformadores.Fácil de usar y altamente automatizado

Se controla mediante programas PLC y se maneja a través de un panel de control de fácil uso, lo que permite cambiar rápidamente de modo, sincronizar los movimientos y reducir la intervención manual.